Your Sustainable Business Partner-ShineVigor

Fuel the fitness, ignite the health & relaxation with ShineVigor!

Strictly Control Quality of Process

Quality is our top priority. From production to delivery, we implement rigorous quality assurance processes at every stage. This ensures all products meet international standards and your specific requirements. We enforce inspection and product compliance, allowing you to focus on your core business.

Raw Material

1. Raw Material Composition: Primarily includes steel, plastics, electronic components, etc. We have stable partnerships with raw material suppliers who have a well-defined Quality Management System.

2.Inventory Management: We maintain ample raw material reserves.

3. Quality Control: Only raw materials that meet specified standards are allowed to proceed to the next production stage.

Key Control Points: Incoming Quality Control (IQC): Inspecting components (motor, belt, control panel) provided by raw material suppliers.

Laser Pipe Cutting

1. High cutting accuracy: positioning accuracy of laser cutting machine is 0.05mm, and repeated positioning accuracy is 0.03mm

2.Fast speed: more than 100 times of wire cutting.

3.The heat affected zone is small and not easy to deform. The cutting seam is flat and beautiful, without subsequent treatment.

4.Stable performance to ensure continuit

Key Control Points: 1.Pre – cutting Inspection 2.Parameter Optimization 3. Real – time Monitoring 4.Post – cutting Inspection

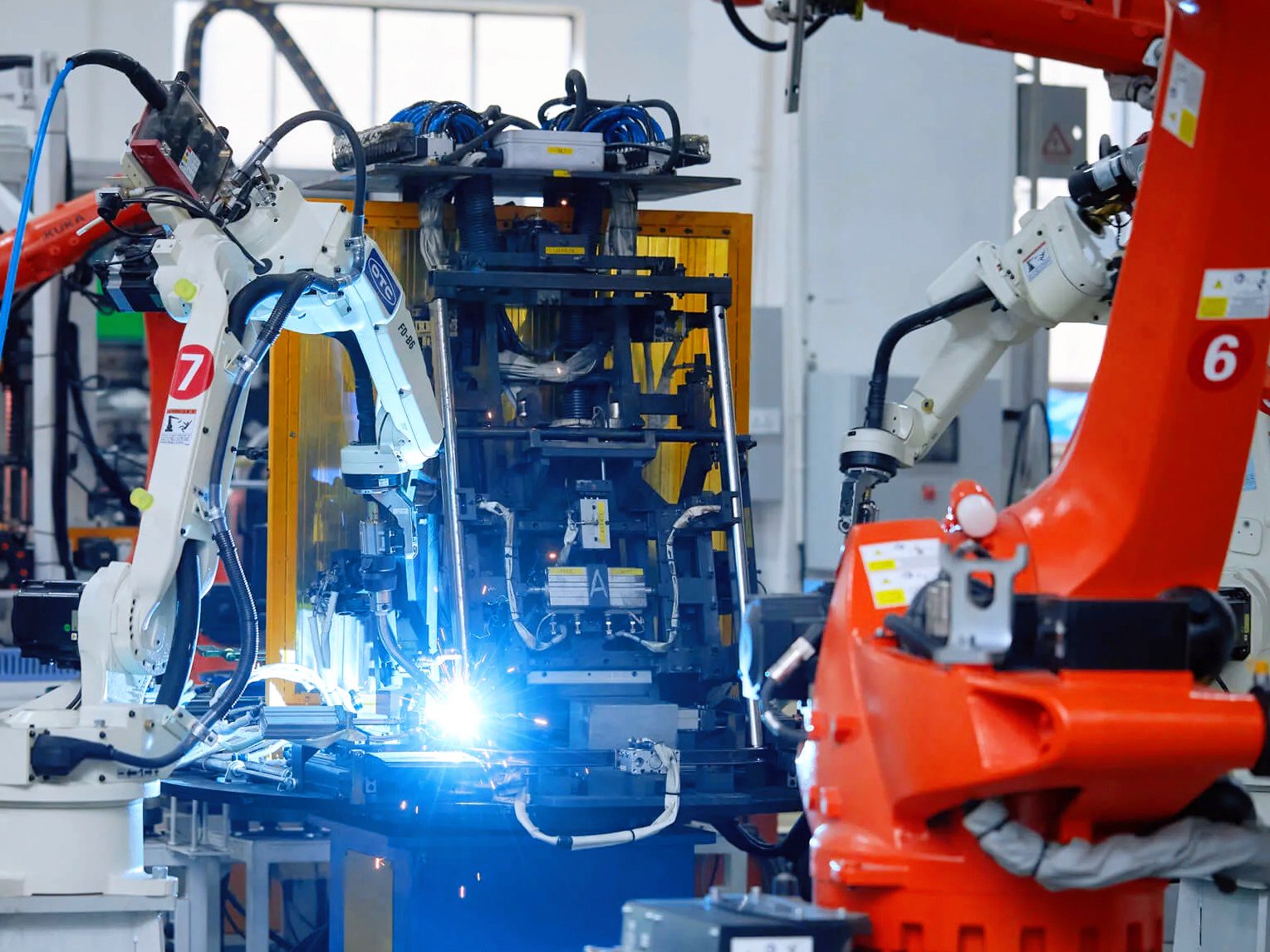

Mechanical Arm Welding

1.Multi-station welding operations save fixture installation time and significantly improve production efficiency.

2.The laser beam can be focused into an extremely small area, making it suitable for welding small parts with very close spacing.

3. It enables high repeatability, repeatable and accurate welding, requires no consumables, offers flexible processing, low operating costs, high automation, and high-speed welding.

Key Control Points: 1.Check that pre-heating and inter-pass temperatures are within the limits. 2.Confirm that the filler material complies with specifications. 3. Other checks: cleaning between passes, weld bead appearance. 4.Non-destructive testing as specified.

Spray painting

The process flow before sanding of the paint line is loading → water avoidance area → pre degreasing → dripping → degreasing → Dripping → Cleaning 1 → Dripping → Cleaning 2 → Double blowing → Drying → Cooling → Unloading

Key Control Points: 1.Raw Material Inspection and Quality Control

2. Maintain consistent temperature and environmental conditions

3. Process Automation and Digital Control Systems 4. Inline and Offline Quality Testing

Production

1.On the assembly line, workers assemble parts in sequence.

2. Each assembly step is inspected to ensure parts are installed correctly and securely. If any problems are found, the part is returned for further processing. 100% real-time testing is conducted during assembly line production to correct defects promptly.

3.Pre-Shipment: Final quality check before goods leave the factory

Key Control Points:

In-Process Quality Control (IPQC) & Pre-shipment Inspection (PSI)

Package & Warehouse

1.Qualified products are cleaned to remove dust and on the surface.

2. Goods are packed with materials such as cartons and foam. The packaging is designed to prevent damage during transportation. Labels with product information, specifications, and precautions are affixed to the packaging.

3.The packaged products are stored in the warehouse and then delivered to customers according to the order requirements.

Key Control Points: safe storage conditions and inventory management.

Transportation and Logistics

1.Supports multiple delivery methods including FOB and EXW. Partners with reputable freight forwarders to arrange reliable transportation (sea/air/express).

2. Container Loading Supervision: inspect the containers arriving at the factory. Also, ensure correct handling and loading to avoid damages.

3. Provides complete shipping documents (commercial invoice, packing list, bill of lading, certification report).

Key Control Points: 1. Visual Inspection:inspect the documents, container, and product packaging details. 2. Train Employees: equipped to identify and address potential issues effectively

Quality Management

Following the ISO 9001:2015 international standard, we possesses a comprehensive quality control process covering the entire lifecycle of R&D, production, assembly, and delivery.

1.R&D and Testing – Rigorous Reliability Testing

Durability Testing: Over 5000 hours of continuous operation to ensure long-term stability.

Load-bearing Testing: maximum load-bearing test to assess the machine’s max loading weight.

Lifespan Testing: impact cycles exceeding 120,000+.

Safety Certification Testing: compliant with standards CE/ROHS/FCC etc.

Drop Testing: to ensure structural integrity. Drop height – 1m for walking pad, 0.6m for home treadmill.

2. Quality Control Team and Processes – 3 Stage

Incoming Quality Control (IQC): Inspecting components (motor, belt, control panel) provided by qualified suppliers.

Process Quality Control (IPQC): 100% testing during assembly line for immediate defect correction before packing.

Pre-shipment Inspection (PSI): Final inspection before shipment (functionality, appearance, packaging).

3. After-sales Guarantee

1-Year Warranty: Covers machine, motors, frames, and core electrical components.

Free Spare Parts Supply: Necessary replacement parts (e.g., running belts, lubricants) are provided for bulk orders.

24-Hour Response: A dedicated after-sales team resolves quality issues within 24 hour.

Why choose us?

Multiple Product Support

With the advantages of diverse and high-quality products, clients can have their goods delivered faster and better. Also, meets needs of clients for purchasing different products.

Your Sustainable Business Partner

Reliable Supplier for Your Business

As a professional supplier, we are committed to meeting your needs. With a mature system, we handle everything from your initial requirements to shipment, creating an efficient and convenient procurement experience for you.

Ensuring High-Quality Standards at Every Stage

Quality is our top priority. From production to delivery, we strictly control the quality assurance process at every stage to ensure all products meet standards. We handle all testing and inspection, allowing you to focus on your core business.

Customized Product Development to Your Needs

If your company requires customized products, ShineVigor is dedicated to serving you. We work closely with you, handling design, prototyping, and production from concept to final delivery. Our team ensures all your requirements are met, the final product meets your expectations, and we efficiently manage the entire process to ensure projects are completed on time and as agreed.

Timely Delivery and Streamlined Logistics

Through effective management of inventory, raw material suppliers, and processes, we ensure the timely and efficient delivery of your products. We also offer flexible logistics and transportation solutions to meet your individual needs. Our experienced logistics team coordinates every step from shipment to customs clearance.

Comprehensive After-Sales Support

Our relationship with you doesn’t end with delivery. We provide ongoing support, answering any questions you may have after delivery or providing suggestions for improvement. Whether it’s answering customer inquiries or assisting you with future procurement, we are committed to serving you, ensuring the smooth operation of your business, and helping you achieve long-term success.

Commit to Building Long-Term Partnerships

Based on our integrity and sincere cooperation, clear and achievable goals, regular and transparent communication, and adaptation to changing market demands, we are committed to building sustainable business partnerships to achieve long-term, win-win cooperation.

FAQs

Q: What is MOQ? A: For stock products, MOQ is 10pcs. For customization, MOQ is from 50pcs

Q: What’s your customization service?

A: Customzton is one of our core strengths. We routinely handle projects involving OEM, ODM, logo, size, material and function settings etc.

Q: What is the delivery time? A: Customized products take approximately 20-30 days to arrive. For larger orders, the lead time is 30-45 days. Delivery days for stock ones is within 7 days.

Q: What’s payment methods are supported? A: TT, L/C, etc.

Q: Which port is in FOB? A: Ningbo or Shanghai port

Q: Can we order one sample first ? Sample can custom the color and add logo ?

A:Yes, we support to make sample , and can custom the color and add logo on machine. Carton will be used in normal version for sample.

Q:What is the packaging way? A: Normal package is polybag+carton. If you have special request, pls let us know.

Q: How is quality controlled before shipping?

A: We ensure quality by following the key steps: 1. Laboratory testing before mass production. 2.With certificates -meet global safety and performance standards. 3. Raw material inspection. 4. 100% testing before packaging. 5. Final inspection before shipment.

Q: What international certifications does the product have?

A: CE, EMC, FCC, and other certifications.

Q: What is the warranty period?

A: 1-year warranty for machine. We also supply free spare parts for replacement.

Q:Is the after-sales service available?

A: Our after-sales service team provides 24/7 online support, analyzed by our technical and after-sales teams. For general issues, resolution time: <4 hours. For complex issues: <24 hours.