Fuel the fitness, ignite the health & relaxation with ShineVigor!

More than a manufacturer and distributor, we focus on helping to achieve your long-term goals.

Strictly Control Quality of Each Process

Raw Material

Raw materials mainly include steel, plastic, electronic components, etc. Only raw materials that meet the specified standards are allowed to enter the next production process.

We have sufficient raw material reserve.

Laser Pipe Cutting

1. High cutting accuracy: positioning accuracy of laser cutting machine is 0.05mm, and repeated positioning accuracy is 0.03mm

2. Fast speed: more than 100 times of wire cutting.

3. The heat affected zone is small and not easy to deform. The cutting seam is flat and beautiful, without subsequent treatment.

4. Stable performance to ensure continuit

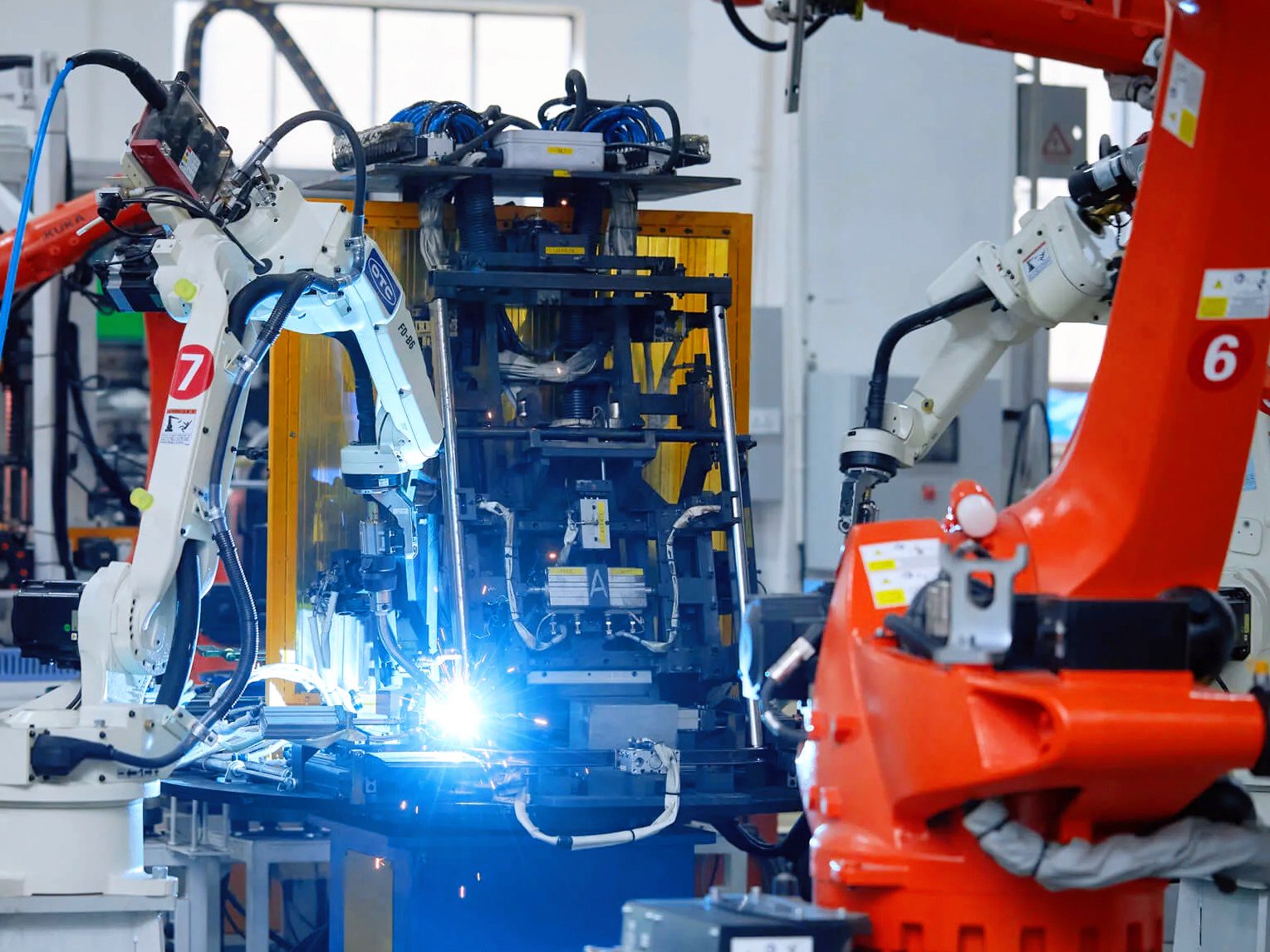

Mechanical Arm Welding

1. Multi station welding operation saves fixture installation time and greatly improves production efficiency.

2. Some places can replace manual operation, suitable for welding in some difficult spaces.

3. The laser beam can be used to weld small and closely spaced parts by focusing on a very small area.

4. High repetition accuracy, repeated and correct welding, no consumables, flexible processing, low operating cost ,high automation integration, high speed welding can be realized.

Spray painting

The process flow before sanding of the paint line is loading → water avoidance area → pre degreasing → dripping → degreasing → Dripping → Cleaning 1 → Dripping → Cleaning 2 → Double blowing → Drying → Cooling → Unloading

Production Line

1. On assembly line, workers install parts in sequence.

2. Each assembly step is checked to ensure that the parts are installed correctly and securely. If there are any issues, the parts are returned for resolution.

3. Only after the tests are qualified will the products be transferred to the packaging team for wiping and packaging.

Package & Warehouse

1. Qualified products are cleaned to remove dust and on the surface.

2. Goods are packed with materials such as cartons and foam. The packaging is designed to prevent damage during transportation. Labels with product information, specifications, and precautions are affixed to the packaging.

3. The packaged products are stored in the warehouse and then delivered to customers according to the order requirements.

Why choose us?

Experienced In export

Services

Complete the entire export process safely, quickly and efficiently. Our goal is to help you realize your vision. We provide one-stop professional pre-sales, in-sale and after-sales services